Key Takeaways

- Fulfillment drag slows growth and hurts customer trust

- Most shipping “automation” is partial and still manual

- Magento + ShipStation unlock real automation through syncing

- Batch label printing and multi-carrier logic speed up shipping

- Integration improves CX, loyalty, and operational agility

- Fulfillment can shift from a bottleneck to a growth lever

Your product catalog is dialed in. The Magento platform runs smooth. Customers click “Buy” — and then, the invisible slowdown begins.

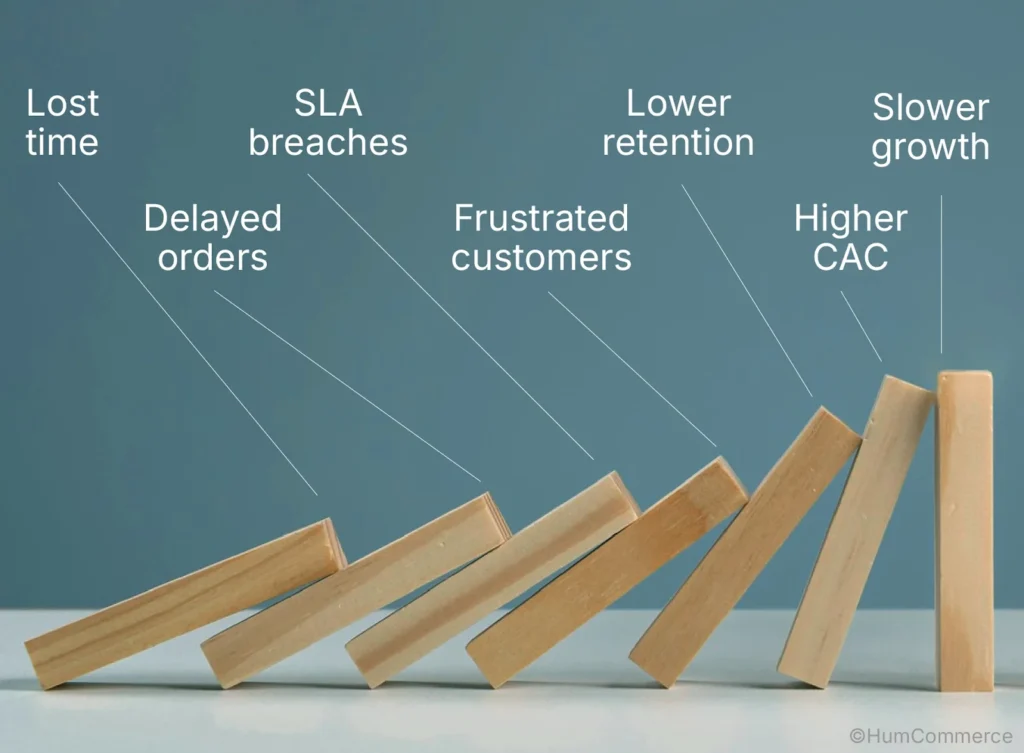

We call it Fulfillment Drag.

It’s not a bug. It’s not a broken label printer. Creeping friction builds up in complex B2B operations when fulfillment becomes a back-office task instead of a growth-critical system.

And in B2B? That drag shows up everywhere:

- Orders arrive as PDFs, POs, or EDI files and rekeyed manually

- Partial shipments require special handling, but the rules live in someone’s head

- Carrier selection is inconsistent, often based on memory or habit

- Inventory updates lag across systems, leading to overselling or missed SLAs

- Support teams field “Where is my order?” tickets from frustrated partners

It’s not always dramatic — at first. But the deeper your catalog, the more warehouses you operate, and the more delivery timelines you’re accountable to, the more dangerous fulfillment drag becomes.

And the kicker? It compounds silently.

Fulfillment Drag Is Slowing Down B2B Growth — You Just Can’t Always See It

At HumCommerce, we’ve seen this firsthand across industries like industrial supply, building materials, and automotive distribution. The difference between teams that scale and those that stall often comes down to one overlooked capability:

How well your order flow is connected.

This isn’t about buying a plugin. It’s about designing a fulfillment strategy where your platforms — ERP, Magento, WMS, ShipStation, and more — talk to each other intelligently.

This article lays out how we do that at HumCommerce:

- A new way to define Fulfillment Drag

- A blueprint for connected fulfillment

- Real-world industry examples with B2B KPIs

- And the architecture strategy behind scaling order-to-ship performance

If fulfillment still feels like resistance, not momentum — this one’s for you.

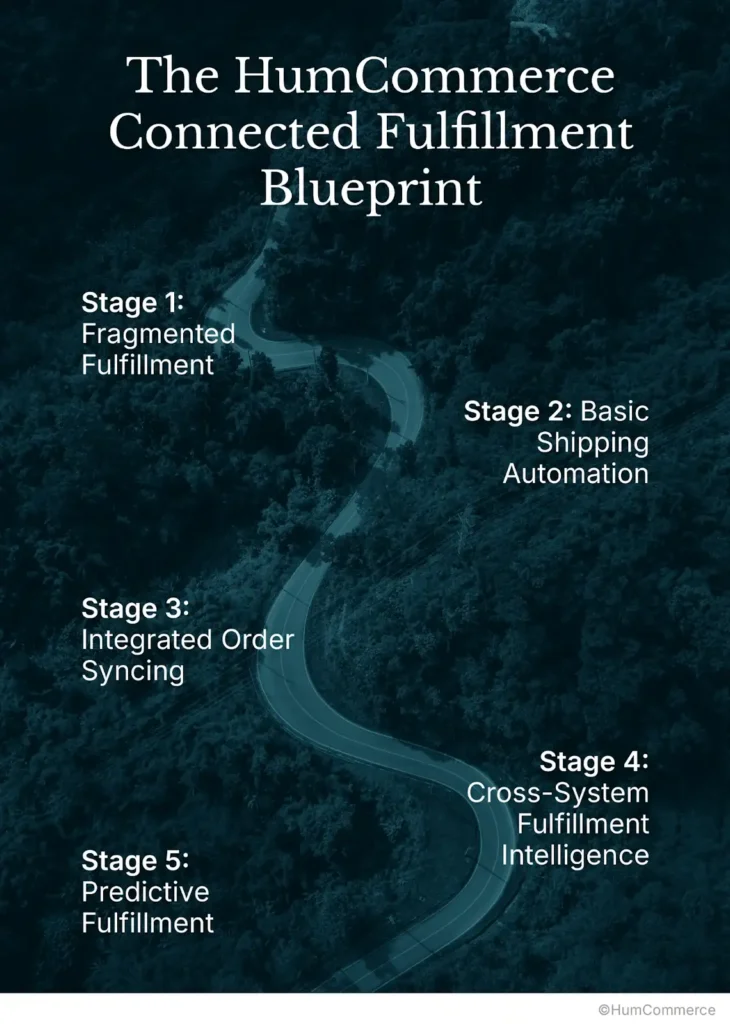

The HumCommerce B2B Fulfillment Integration Strategy

We see scaling fulfillment as less about adding new apps and more about building real resilience.

It’s about setting up a system that bends when demand spikes, adapts when things shift unexpectedly, and stays dependable even when the pressure’s highest.

Stage 1: Fragmented Fulfillment

When fulfillment’s still stuck in the early stages, it usually looks something like this:

Orders show up from every possible channel — emails, old customer portals, even stray PDFs someone forgot were still active.

Inventory updates happen late, out of order, or not at all — depending mostly on who remembers first.

Teams patch gaps with “tribal knowledge” instead of formal processes — meaning things work fine until someone’s sick or leaves.

Carrier choices? Mostly guesswork, with little real strategy behind them.

And the fallout

Missed deadlines, unhappy customers, overloaded support teams… and a whole lot of reshipping costs nobody budgeted for. Instead, inventory updates tend to show up after the fact — and often don’t match what’s actually happening on the floor.

Stage 2: Basic Shipping Automation

After the early chaos, most teams reach for tools — shipping apps, label generators, basic automations — and at first, it feels like real progress.

But without deeper system integration, some of the old issues just sneak back in through the cracks.

You’ll know you’re here if:

You’ve wired a shipping app into your eCommerce platform… but syncing still falls behind when orders stack up.

You can batch-print labels now (huge time-saver), but the whole process still feels shaky when volume spikes.

Special-case orders (the complicated ones) still have to be handled manually, creating bottlenecks you can’t predict.

Tracking updates and carrier choices improve a bit, but still require too much chasing and patchwork fixes.

Where things stand

- You’re moving faster than before, but you’re still vulnerable.

- Every time order volume spikes, the cracks show up and your team feels it first.

Stage 3: Integrated Order Syncing

Things finally start to click into place.

You’ll notice:

Magento, ShipStation, and your ERP syncing orders automatically — no double entry needed.

Smart shipping rules kicking in — matching orders to the right carrier based on what actually matters: cost, speed, service level.

Tracking numbers coming back fast, cleanly — so customers aren’t stuck refreshing email inboxes all day.

The real payoff

- Orders move the way they’re supposed to.

- Mistakes shrink.

- And your team gets back the hours they used to waste fixing preventable messes.

Stage 4: Cross-System Fulfillment Intelligence

Fulfillment stops reacting. It starts staying three steps ahead.

Most teams hitting this stage start to see:

Shipping rules flex automatically — adjusting by warehouse, customer, or even region — without people needing to step in.

Failed syncs triggering instant alerts (plus automatic fallbacks), so orders don’t get stuck in limbo.

Orders carrying rich metadata — not just for SLA reporting, but to power real fulfillment insights.

Fulfillment data becoming part of customer strategy — not just an operational afterthought.

At this point, fulfillment steps out of the background and into a role that actually drives growth, speed, and smarter customer journeys.

Stage 5: Predictive Fulfillment

When everything clicks, fulfillment stops demanding your attention every day because it just works in the background, quietly powering everything forward.

Before long, you’ll notice some big shifts:

High-risk orders get pulled into priority workflows early — often before anyone even realizes there could’ve been an issue.

Carrier selection starts to lean on actual delivery performance, not promises made during flashy demos.

Cost-efficiency and sustainability goals aren’t afterthoughts anymore; they’re baked right into how routing decisions happen, automatically.

And here’s where it really changes:

Instead of constantly chasing lost orders or untangling mistakes, your teams spend their time fine-tuning a system that’s already designed to handle the load without needing hands-on babysitting every day.

The Strategic B2B Friction Behind Fulfillment Drag

What B2B Fulfillment Drag Really Looks Like (and Why It’s So Costly)

In B2B, fulfillment isn’t just shipping. It’s a contract. A commitment. A risk surface.

And when that fulfillment is slow, fragmented, or error-prone — it annoys customers, while also undermining revenue, partnerships, and brand trust.

Here’s where Fulfillment Drag shows up in complex B2B setups:

Manual Order Processing (Even with EDI)

In a lot of companies, orders still come in the old-school way — emails, PDFs, EDI feeds that someone has to babysit. Instead of flowing cleanly into Magento or the ERP, line items often get retyped manually, even when there’s supposed to be “integration.”

Every time there’s an issue, like a partial shipment or a special configuration, the whole process slows to a crawl, because someone has to double-check it manually.

Over time, that adds up: orders drag out longer, mistakes slip through, and ops teams end up spending way too much time firefighting instead of moving orders forward.

Multi-Warehouse Chaos Without Smart Routing

Inventory might be split across several warehouses, DCs, or even 3PLs — but without automation, picking the right stock feels like guesswork.

Sometimes the wrong location ships the order. Other times, shipments get split when they didn’t need to be, just because no system is making decisions based on inventory or location.

Carrier choices? Still based on habit, not real data.

The fallout: More missed SLAs, higher shipping bills, and worse delivery reliability across the board.

SLA Pressure That Burns Ops Teams Out

A lot of B2B deals hinge on tight delivery windows and guaranteed service levels.

When delivery windows get missed — and they will, without automation — penalties, chargebacks, and even lost clients start creeping in fast.

The worst part? Meeting SLAs turns into a daily scramble, with ops teams stuck pulling last-minute saves over and over.

The fallout: After a while, it wears people down, breaks processes, and starts eating into margins you can’t afford to lose.

Reverse Logistics and Returns Chaos

Returns (RMAs) should be simple, but often turn messy. Items need condition checks, lot tracing, approvals and when it’s all manual, delays pile up fast.

Returned products sometimes don’t sync back into Magento or the ERP properly, meaning inventory counts drift, and credits take forever to process.

The fallout: The results aren’t pretty: frustrated partners chasing refunds, piles of inventory sitting in limbo, and finance teams scrambling to clean up the cash flow mess it leaves behind.

Disconnected Systems, Conflicting Data

When Magento, WMS, and shipping platforms each tell a slightly different story, it’s a nightmare. Addresses mismatch. Inventory counts are off. And no one’s quite sure which system has the “real” version of the truth.

The fallout: More fulfillment mistakes, delayed shipments, and support teams buried under complaints.

At HumCommerce, this is the reality we walk into every week. And we redesign how order data flows, how logic is enforced, and how fulfillment becomes a coordinated strategy instead of a cost center.

Because the real cost of Fulfillment Drag?

It’s not time. It’s trust. And once that erodes, revenue isn’t far behind.

From Drag to Drive — How Smarter Fulfillment Powers Real Growth

When Fulfillment Starts to Actually Flow

Most businesses don’t feel the drag of disconnected fulfillment until it’s already slowing everything else down.

A lot of platforms will “connect” your systems — but plugging things together isn’t enough.

At HumCommerce, we focus on building real bridges between Magento, ShipStation, and your ERP, the kind that actually hold up under real-world volume and pressure.

Once the systems start syncing properly, you’ll feel the difference right away:

1. Orders Move When They’re Supposed To

No more waiting for batch uploads or wondering if a sync actually went through.

Instead:

- Orders slip from Magento into ShipStation without lag — so ops teams aren’t stuck chasing down missing orders all afternoon.

- Stock levels stay close to real-time — not perfect, but good enough that teams can trust what they’re seeing.

- Order statuses update automatically across systems — no more double-checking every few hours just to make sure something moved.

And the ripple effect? There’s a lot less manual scrambling, and a lot fewer “Where’s my order?” emails to sort through.

2. Fulfillment Stops Guessing and Starts Thinking

When routing runs on logic instead of “what feels right,” everything speeds up naturally.

You’ll often see:

- Carrier choices happening automatically, based on the best mix of cost, speed, and zone — without someone stepping in every time.

- Warehouses getting assigned based on live stock numbers — not whoever picks up the phone first.

- Split shipments and edge cases handled quietly behind the scenes most of the time.

The real win? Shipping gets cheaper, faster, and way less stressful for everyone involved.

3. Batch Label Processing That Actually Scales

This isn’t just batch-printing faster — it’s real operational flow at volume.

With integrated operations:

- Teams can crank out hundreds (or thousands) of labels with a few clicks.

- No hand-checking SKUs, no writing notes on sticky labels.

- Supports different packaging rules, regional label standards, and auto-generated return slips.

The payoff: Ops teams do more with less — without needing to staff up every time order volume surges.

4. Catching Problems Early — Before They Become Painful

Even the best systems hit snags.

The difference with smart fulfillment?

The snags don’t stay hidden.

When fulfillment’s connected properly:

- Sync hiccups don’t stay hidden — alerts go out fast so fixes happen before customers ever notice.

- If addresses don’t match, SKUs are missing, or pricing looks off, the system usually catches it on the first pass.

- Exceptions land where they should — with ops teams who can fix them quickly, without digging through endless logs.

The biggest difference you’ll feel? Fewer last-minute fire drills — and way more time spent actually moving orders out the door.

5. Closing the Loop With Customers — Not Leaving Them Hanging

Customers don’t care about the systems behind the scenes. They care if their order’s late — or missing.

Here’s how smart fulfillment keeps them happy:

- Tracking numbers and branded shipping updates go out the second an order ships.

- Returns aren’t just easier — they’re faster, with quicker credit processing.

- Your analytics start pulling in fulfillment data too — not just clicks and conversions.

Real result? Happier customers. More repeat buyers. And a post-purchase experience that actually builds loyalty — instead of breaking it.

How B2B Leaders Are Beating Fulfillment Drag With Data

Industry Spotlights – Scalable Fulfillment in the Real World

HumCommerce has helped B2B brands across verticals turn fulfillment from a liability into a strategic asset. Below are two sector-specific examples that show what’s possible when the right integration architecture is applied.

Real-World Use Case: Automotive Parts Distribution

A parts distributor handling dealership and service center orders wasn’t just fighting complexity — they were racing the clock.

Every VIN-specific part, every warranty replacement mattered. And if Vehicle Off Road (VOR) shipments got delayed? Customers, and dealership relationships, were on the line.

The biggest hurdles:

- Freight modes mixed in unpredictable ways, making it tough to prioritize urgent deliveries.

- VOR orders kept getting bogged down in the general fulfillment queue.

How to fix it: A priority-driven integration between Magento, ShipStation, and their warehouse systems, automatically ranking orders by urgency, type, and SLA targets.

In the real world, you’d probably start seeing changes like this:

- Service bays wouldn’t be waiting quite so long on critical VOR parts — a lot fewer vehicles stuck on lifts for days.

- On-Time In-Full rates might start ticking up, especially in regions where delays were a constant struggle.

- Dealerships could finally count on parts showing up when promised — which makes a bigger difference than most people think when it comes to customer trust.

- And fulfillment teams might spot underperforming warehouses earlier, before missed deadlines turned into full-blown SLA headaches.

Making It Work: The Integration Blueprint That Delivers

You Don’t Need a New Stack — You Just Need a Smarter Map

The real challenge? They aren’t talking to each other well enough.

At HumCommerce, we almost never recommend replacing your whole fulfillment stack. Most B2B brands already have the right pieces — Magento (or another eCommerce platform), ShipStation (or a shipping engine), and ERP/WMS systems that keep inventory and operations running.

That’s where smart integration architecture comes in: connecting the right dots, and making the right rules without adding layers of unnecessary complexity.

Who Owns What — And How It Should Work Together

Magento (or your eCommerce platform)

- At the front end, this is where orders land first.

- It’s also where promotions, special pricing rules, and contract agreements get applied automatically — so sales teams don’t have to babysit every deal.

- Magento connects customer orders straight to payment systems, keeping everything clean from the first click.

ShipStation (or your fulfillment engine)

- Behind the scenes, ShipStation figures out the best way to ship — based on location, cost, delivery speed, and a few smart rules.

- It also handles the heavy lifting of batch printing labels (hundreds at a time, when needed) and pushes real-time tracking info back to the eCommerce and ERP layers.

- If you’re using 3PLs or outside warehouses, ShipStation can bridge those gaps too — no extra software required.

ERP or WMS (your existing systems)

Most of the day-to-day grind lives here — inventory tracking, purchase orders flying around, warehouse stock shifting as orders come in and go out.

Instead of static numbers, the ERP keeps Magento updated with what’s actually available — so customers aren’t placing orders for stuff that’s already gone.

And when things come back (returns, restocks, refunds), this is the system that helps everything line up again across finance, ops, and customer accounts.

How HumCommerce Connects the Dots

We don’t believe in tearing down systems that already work.

In a lot of cases, the right tools are already sitting there they just aren’t talking to each other the way they should. We help build the bridges that make it happen, connecting Magento, ShipStation, and your ERP or WMS through API links or middleware, whichever setup fits best for what you’re running.

The goal? Keep product data, orders, pricing, and inventory flowing naturally, so teams aren’t stuck tracking down missing updates or fixing broken handoffs all the time.

How It All Ties Together

When the pieces are finally connected the right way, fulfillment stops feeling stitched together — and starts acting like a real system. Even if your stack didn’t start out perfectly matched, smart integration can make it move like one.

Is This a Full OMS Replacement? Not Quite.

We get this question a lot — so here’s the simple answer:

We’re not tearing out your ERP or installing a brand new OMS. What we build strengthens the “order-to-ship” layer — the stretch where fulfillment either wins you loyalty… or costs you trust.

And in most setups, this approach actually makes your existing OMS work better by:

- Keeping order and inventory data flowing between systems without gaps.

- Killing off redundant processes that used to eat up team hours.

- Automating your business rules so no one’s hand-keying discounts or pricing overrides.

- Making returns, tracking updates, and refunds a whole lot smoother — for both your teams and your customers.

What a Scalable Magento + ShipStation Setup Should Always Include

When we design fulfillment stacks, certain things are non-negotiable:

- Orders, inventory, and tracking data sync in both directions — fast, not batch-delayed.

- Shipping logic adapts based on product tags (like fragile, bulk) and customer geography.

- Exceptions (bad addresses, incomplete orders, weird splits) don’t stay hidden — the system flags and routes them automatically.

- Return workflows bring inventory back into the system correctly — and trigger refunds without manual chasing.

- Fulfillment feeds back into CX and marketing data — so you can actually segment customers by delivery experience, not just what they clicked on.

And maybe most importantly? We build it so you can grow — without having to rebuild everything six months later.

Eliminate the Drag. Accelerate the Growth

Not a Back-End Function, But Fulfillment a Growth Lever

In B2B commerce, you can’t out-market a broken fulfillment engine.

Your buyers expect speed, accuracy, and consistency, especially after they click “place order.”

That’s why at HumCommerce, we treat fulfillment not as an afterthought, but as a strategic capability. Because every touchpoint after purchase is either building loyalty… or eroding it.

When fulfillment works, you’re shipping faster and growing smarter.

- Orders get routed automatically, with logic that reflects your real-world complexity

- Inventory stays accurate across all systems — not just on paper

- Shipments go out faster, cheaper, and more predictably

- Customers know exactly what to expect, and when

- Your ops team finally gets out of firefighting mode

This is the system modern B2B brands need and it’s the system we design.

Let’s Build Fulfillment That Actually Scales

You don’t need more plugins. You need a smarter map and a partner that knows how to execute it.

At HumCommerce, we specialize in turning fulfillment complexity into performance.

We help B2B teams design, connect, and automate their order flows, using the systems they already have, configured to work together at scale.

Want to identify the drag points in your current stack?

We’ll walk you through a fulfillment architecture audit and map a plan to fix what’s slowing you down.

Schedule Your Fulfillment Integration Review

Author Note

This guide was developed by HumCommerce, a digital transformation partner for B2B companies in manufacturing, distribution, construction, and supply. We specialize in complex eCommerce architecture, ERP/PIM integration, and fulfillment automation, turning disconnected platforms into unified growth engines.